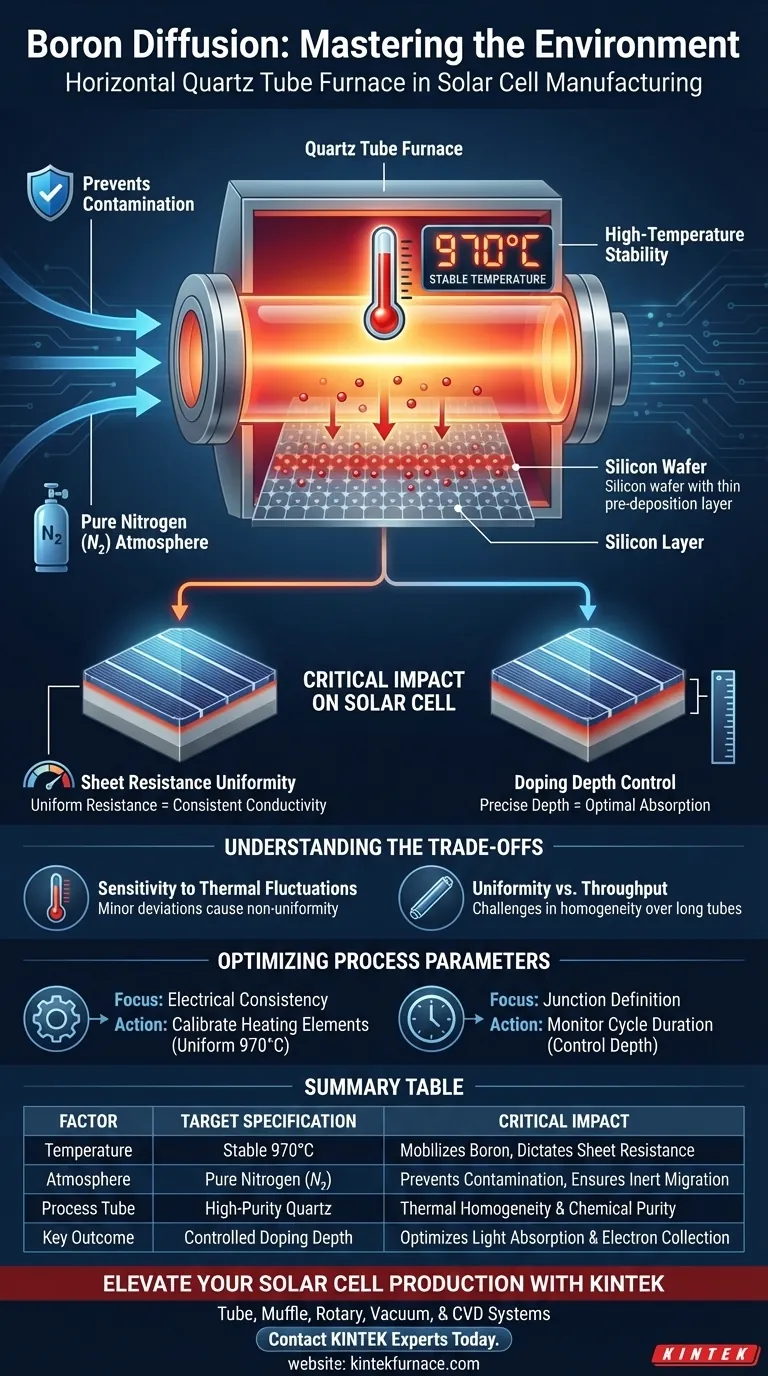

A horizontal quartz tube furnace specifically creates a rigorous thermal environment characterized by a stable temperature of approximately 970°C and a pure nitrogen atmosphere. These specific conditions are engineered to facilitate the migration of boron atoms from a pre-deposition layer into the silicon substrate, a critical step in forming the solar cell's emitter region.

Precision in thermal management is the primary driver of emitter quality. By maintaining a strict high-temperature nitrogen environment, the furnace ensures the uniformity of sheet resistance and the accuracy of doping depth essential for efficient solar cells.

The Critical Environmental Factors

High-Temperature Stability

The core function of the furnace is to reach and maintain a target temperature of 970°C. This specific thermal energy level is required to mobilize boron atoms.

Without this precise heat, the boron cannot diffuse effectively from the surface layer into the silicon lattice.

The Nitrogen Atmosphere

The diffusion process takes place within a controlled nitrogen environment. This inert atmosphere is crucial for isolating the wafers during the high-heat cycle.

It ensures that the boron migration occurs without interference from oxygen or other atmospheric contaminants that could degrade the silicon surface.

Impact on Solar Cell Architecture

Determining Sheet Resistance

The furnace's ability to hold the temperature at exactly 970°C directly dictates the sheet resistance uniformity of the final product.

Uniform resistance across the wafer is necessary for consistent electrical conductivity. Variations in temperature will lead to variations in resistance, impacting the cell's output.

Controlling Doping Depth

The thermal environment also defines the doping depth of the emitter. The depth is a function of how long the silicon is exposed to the 970°C heat.

Precise control allows manufacturers to achieve the exact junction depth required for optimal light absorption and electron collection.

Understanding the Trade-offs

Sensitivity to Thermal Fluctuations

The primary trade-off in this process is the extreme sensitivity to temperature variations.

Because the diffusion rate is exponentially dependent on temperature, even minor deviations from the 970°C setpoint can cause significant non-uniformity.

Uniformity vs. Throughput

Maintaining perfect environmental homogeneity across a long horizontal tube can be challenging, especially when processing large batches.

If the nitrogen flow or temperature gradient varies along the length of the tube, wafers at different positions may exhibit different electrical properties.

Optimizing Process Parameters

To achieve the best results with a horizontal quartz tube furnace, align your operational focus with your specific manufacturing goals:

- If your primary focus is Electrical Consistency: Prioritize the calibration of heating elements to ensure the 970°C temperature is uniform across the entire length of the tube.

- If your primary focus is Junction Definition: Strictly monitor the duration of the cycle under the nitrogen atmosphere to control the exact doping depth.

Success in boron diffusion ultimately relies on the absolute precision of your thermal and atmospheric controls.

Summary Table:

| Environmental Factor | Target Specification | Critical Impact on Solar Cell |

|---|---|---|

| Temperature | Stable 970°C | Mobilizes boron atoms & dictates sheet resistance |

| Atmosphere | Pure Nitrogen ($N_2$) | Prevents contamination & ensures inert boron migration |

| Process Tube | High-purity Quartz | Maintains thermal homogeneity & chemical purity |

| Key Outcome | Controlled Doping Depth | Optimizes light absorption and electron collection |

Elevate Your Solar Cell Production with KINTEK

Precision thermal management is the difference between a standard cell and a high-efficiency power source. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Tube, Muffle, Rotary, Vacuum, and CVD systems tailored for the rigorous demands of semiconductor and solar manufacturing.

Whether you need custom dimensions or specific atmospheric controls for boron diffusion, our lab high-temp furnaces are customizable to your unique research or production needs.

Ready to achieve perfect sheet resistance and doping uniformity?

ビジュアルガイド

参考文献

- Hakim Korichi, Ahmed Baha-Eddine Bensdira. Investigating the influence of boron diffusion temperature on the performance of n-type PERT monofacial solar cells with reduced thermal steps. DOI: 10.35784/iapgos.6599

この記事は、以下の技術情報にも基づいています Kintek Furnace ナレッジベース .

関連製品

- 1200 ℃ 分割管炉研究室水晶管炉水晶管と

- 1700℃石英またはアルミナ管高温ラボ用管状炉

- 1400℃高温石英アルミナ管状実験室炉

- 化学的気相成長装置のための多加熱帯 CVD の管状炉機械

- 研究用石英管状炉 RTP加熱管状炉

よくある質問

- 石英管炉はダイヤモンドの水蒸気アニーリングをどのように促進しますか? 500℃での界面安定性の向上

- 石英管炉の清掃方法とは?安全で汚染のないメンテナンスのための必須手順

- チューブファーネスはCFeSエアロゲルにどのような環境条件を提供しますか?マスターカーボン化と不活性保護

- 多層グラフェン(MLG)の作製におけるCVDチューブ炉の主な機能は何ですか?専門家ガイド

- プログラム可能な管状還元炉の重要な役割は何ですか?精密な触媒活性化を実現する

- クロム鉄鉱の還元における水平管状炉の役割は何ですか?マスター精密固相プロセス

- チューブ炉とは何ですか、またその主な用途は何ですか?高温での精度と均一性が不可欠です

- BN@PyCエアロゲルの二段階熱処理における高温管状炉の具体的な役割は何ですか?