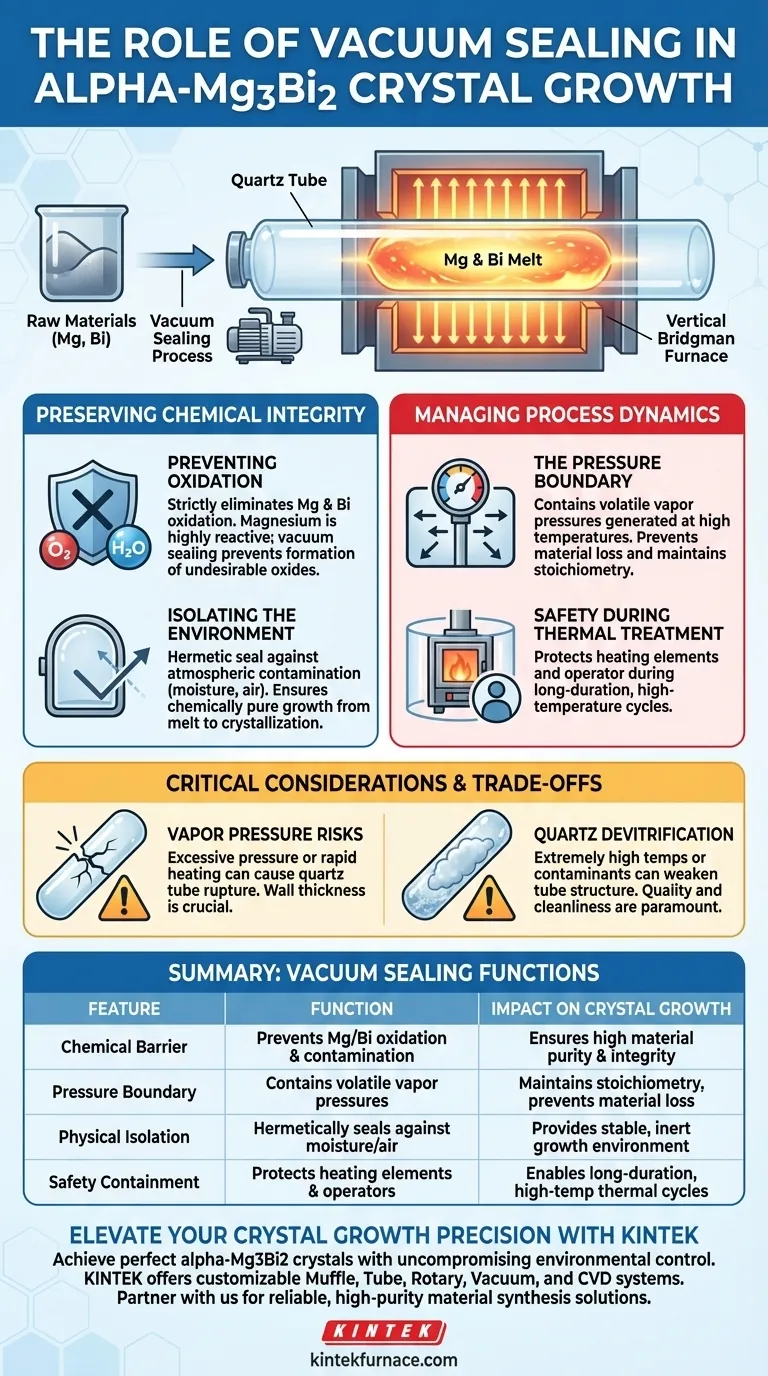

The primary purpose of vacuum sealing raw materials in a quartz tube for alpha-Mg3Bi2 crystal growth is to create an isolated, chemically inert environment. This step serves to strictly prevent the oxidation of metallic magnesium (Mg) and bismuth (Bi) during high-temperature melting, while simultaneously acting as a critical pressure boundary to ensure process safety during long-duration thermal treatments.

Core Insight Vacuum sealing serves a dual role: it acts as a chemical barrier against atmospheric contamination (specifically oxygen and moisture) and a physical containment vessel. Without this isolation, the high reactivity of magnesium would degrade the material purity, and the internal pressures generated during the vertical Bridgman process could compromise the growth furnace.

Preserving Chemical Integrity

To grow high-quality alpha-Mg3Bi2 crystals, maintaining the precise chemical composition of the melt is non-negotiable. The vacuum sealing process is the first line of defense in material synthesis.

Preventing Oxidation

Magnesium and bismuth are susceptible to oxidation at high temperatures. Magnesium, in particular, is highly reactive with oxygen. If exposed to air during the melting phase, the raw materials would form oxides rather than the desired crystal compound. Vacuum sealing eliminates this variable entirely.

Isolating the Environment

The quartz tube acts as a hermetic seal against the ambient atmosphere. This isolation prevents moisture and other airborne contaminants from entering the melt. It ensures that the growth environment remains chemically pure from the initial melting stage through to crystallization.

Managing Process Dynamics

Beyond chemical purity, the quartz tube serves a structural function. The alpha-Mg3Bi2 growth process typically utilizes the vertical Bridgman technique, which imposes specific physical demands on the containment vessel.

The Pressure Boundary

During high-temperature synthesis, the volatile components within the tube can generate significant internal vapor pressure. The sealed quartz tube acts as a robust pressure boundary. It contains these vapors, preventing material loss that would alter the stoichiometry (the ratio of Mg to Bi) of the final crystal.

Safety During Thermal Treatment

The crystal growth process involves long-duration thermal treatments. The sealed tube protects the furnace heating elements and the operator by containing the melt. This ensures that the process remains safe and stable throughout the extended heating and cooling cycles required for single crystal growth.

Critical Considerations and Trade-offs

While vacuum sealing in quartz is the industry standard for this process, it is not without physical limitations that must be managed.

Vapor Pressure Risks

Although the tube acts as a pressure boundary, there is a limit to the internal pressure a quartz tube can withstand. If the temperature is raised too quickly or exceeds the design limits of the tube's wall thickness, the internal vapor pressure of the magnesium can cause the tube to rupture.

Quartz Devitrification

At extremely high temperatures or in the presence of certain contaminants, quartz can undergo devitrification (crystallization). This weakens the structural integrity of the tube. While quartz is generally suitable for Mg-Bi growth temperatures, the tube quality and cleanliness are paramount to prevent failure during long runs.

Making the Right Choice for Your Project

Success in growing alpha-Mg3Bi2 depends on how strictly you manage the sealing and heating parameters.

- If your primary focus is Material Purity: Prioritize a high-vacuum base pressure (low background pressure) before sealing to remove every trace of oxygen and moisture, as magnesium is unforgiving of contaminants.

- If your primary focus is Process Safety: Calculate the expected vapor pressure of Magnesium at your peak temperature and ensure the quartz tube wall thickness provides a sufficient safety margin against rupture.

Ultimately, the sealed quartz tube is not just a container; it is an active component that defines the chemical purity and physical safety of your crystal growth process.

Summary Table:

| Feature | Function | Impact on Crystal Growth |

|---|---|---|

| Chemical Barrier | Prevents Mg/Bi oxidation and contamination | Ensures high material purity and integrity |

| Pressure Boundary | Contains volatile vapor pressures | Maintains stoichiometry and prevents material loss |

| Physical Isolation | Hermetically seals against moisture/air | Provides a stable, inert growth environment |

| Safety Containment | Protects heating elements and operators | Enables long-duration, high-temp thermal cycles |

Elevate Your Crystal Growth Precision with KINTEK

Achieving the perfect alpha-Mg3Bi2 crystal requires uncompromising environmental control and thermal stability. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other high-performance lab high-temp furnaces—all fully customizable to meet your unique research requirements.

Don't let oxidation or pressure instability compromise your results. Partner with KINTEK for reliable, high-purity material synthesis solutions. Contact us today to discuss your project and request a custom quote!

ビジュアルガイド

参考文献

- Mingyuan Hu, Jiaqing He. Helical dislocation-driven plasticity and flexible high-performance thermoelectric generator in α-Mg3Bi2 single crystals. DOI: 10.1038/s41467-024-55689-7

この記事は、以下の技術情報にも基づいています Kintek Furnace ナレッジベース .

関連製品

- 1200 ℃ 分割管炉研究室水晶管炉水晶管と

- 1400℃高温石英アルミナ管状実験室炉

- 研究用石英管状炉 RTP加熱管状炉

- 高圧実験室用真空管状炉 水晶管状炉

- 1700℃石英またはアルミナ管高温ラボ用管状炉

よくある質問

- カスタム真空炉はどのようにして正確な温度制御を実現するのですか?研究室で優れた熱均一性を実現しましょう

- 真空炉と空気炉では熱伝達はどのように異なりますか?研究室のための重要な洞察

- 真空炉の一般的な産業用途は何ですか?材料の品質と性能を向上させる

- 真空炉を使用するメリットとデメリットは何ですか?精密な熱処理を解き放つ

- SiC-Al含浸における高温真空炉のメカニズムとは?複合材のプロセスをマスターする

- 不消耗型真空アーク溶解炉の機能とは? FeSiBPCCuNb合金合成における高純度化の達成

- 真空炉の主な用途は何ですか?航空宇宙および医療分野向けの超高純度熱処理を実現

- 真空炉を使用する利点は何ですか?優れた冶金制御と純度を実現する