熱処理でアルゴンを使用する際の主なコストに関する考慮事項は、他の雰囲気ガスと比較して購入価格が高いことです。しかし、この直接的な費用は方程式の一部にすぎません。真の財務的影響は、このコストと、アルゴンが排除できる材料の劣化、手直し、後処理といった、しばしば隠れたコストとを比較衡量することで理解されます。

アルゴンは高い先行投資を伴いますが、本質的にはプロセス制御と最終部品の品質への投資です。使用の決定は単純な計算にかかっています。すなわち、材料の欠陥、酸化、または汚染のコストが、保護ガスのコストを上回るかどうかです。

コストがかかるにもかかわらずアルゴンが使用される理由

コストとベネフィットの分析を理解するためには、まずアルゴンがなぜそれほど効果的なのかを理解する必要があります。その価値は、その基本的な化学的性質に由来します。

不活性の原理

アルゴンは貴ガスであり、化学的に不活性であることを意味します。熱処理に典型的な高温では、金属や炉内の他の元素と反応しません。

この不活性シールドは、酸素や水蒸気などの反応性ガスを追い出すため、すべての利点の基盤となります。

酸化と汚染の防止

最も直接的な利点は、酸化の防止です。高温の金属が酸素にさらされると、表面にスケール層が形成され、これが寸法公差や表面仕上げを損なう可能性があります。

アルゴンは酸素のない環境を作り出し、部品が炉からきれいで光沢があり、スケールがない状態で出てくることを保証します。これは、厳しい仕様を持つ部品にとって極めて重要です。

材料の完全性の保持

チタン、アルミニウム、特定の高合金鋼などの反応性金属の場合、微量の酸素や窒素でさえも材料に拡散し、その機械的特性を変化させる可能性があります。これにより、脆化や疲労寿命の低下につながる可能性があります。

アルゴン雰囲気を使用することで、熱サイクル全体を通して材料の化学的および冶金学的純度が保証されます。

総所有コストの内訳

単にアルゴンの1立方フィートあたりの価格に焦点を当てるのは誤解を招きます。適切なコスト分析では、製造プロセスへの全体的な影響を考慮する必要があります。

直接的なガス費用

アルゴンは、最も一般的な代替品である窒素よりも、製造と精製にコストがかかります。これにより、最も目に見える主要なコスト要因である、直接的な購入価格が高くなります。

間接的な節約:手直しとスクラップの削減

ここにアルゴンの真の価値が現れます。高感度の合金で作られた高価な部品が酸化や汚染によってスクラップになった場合、その部品を保護するために使用されたであろうアルゴンのコストの数百倍、数千倍の金銭的損失となる可能性があります。

アルゴンの使用は、特に航空宇宙、医療、先端電子機器などの分野で、コストのかかる失敗に対する保険として機能します。

間接的な節約:後処理の排除

完全に不活性な雰囲気なしで熱処理された部品は、スケールを除去するためにサンドブラスト、酸洗、または研削などの二次的な工程を必要とすることがよくあります。

これらの工程は、人件費、材料費、製造時間に大幅なコストを追加します。アルゴンは、炉から直接クリーンな部品を生成することで、この高価な後処理サイクルを完全に排除できます。

トレードオフの理解

アルゴンは強力なツールですが、すべての用途に最適な選択肢というわけではありません。客観的な評価を行うには、その限界を認識する必要があります。

高い取得コスト

最も重要なトレードオフは、その初期費用です。一般的な炭素鋼で作られた低コスト、大量生産の部品の場合、完全にクリーンな表面のメリットは、より安価な窒素や変成ガス雰囲気に対するアルゴンのプレミアム価格を正当化しない可能性があります。

アルゴンが過剰となる場合

部品の用途で少量の表面スケールが許容される場合、または熱処理後にいずれにしても機械加工やコーティングが行われる場合、アルゴンの使用はおそらく不要な出費です。重要なのは、雰囲気の要件をコンポーネントの最終的なニーズに合わせることです。

純粋なアルゴン以外の代替品

場合によっては、ガスの混合物がコストと性能のバランスを提供できます。アルゴン-水素混合物は強化された洗浄力を提供でき、高純度窒素は、感度の低い材料に対してより低いコストで「十分な」ソリューションとなる可能性があります。

アプリケーションに最適な選択をする

あなたの決定は、あなたの材料、あなたのプロセス、およびあなたの最終的な部品要件を明確に評価したことに基づいているべきです。

- 高価な材料や反応性材料の処理(例:航空宇宙、医療)が主な焦点である場合: 材料の完全性を保証し、壊滅的な部品の故障を防ぐために、アルゴンはしばしば必須要件となります。

- 後処理を避けるために、明るくきれいな表面仕上げを達成することが主な焦点である場合: アルゴンのコストは、二次的な洗浄および仕上げ工程を排除することによる直接的な節約によって容易に正当化されます。

- 一般的な鋼材のコスト重視の熱処理が主な焦点である場合: アルゴンのプレミアムなメリットがコストに見合わない可能性があるため、窒素や生成雰囲気などのより安価な代替品を検討してください。

結局のところ、アルゴンを消耗品としてではなく、リスク管理のツールとして捉えることが、健全な財務的決定を下すための鍵となります。

要約表:

| コスト要因 | 影響 |

|---|---|

| 直接的なガス費用 | 窒素などの代替品と比較して購入価格が高い |

| 間接的な節約 | スクラップ、手直しを削減し、後処理工程を排除する |

| 材料保護 | 酸化や汚染を防ぎ、完全性を保持する |

| 用途の適合性 | 高価な反応性材料に最適。他の材料には過剰な場合がある |

KINTEKの先進的な炉ソリューションで熱処理プロセスを最適化しましょう!卓越した研究開発と社内製造を活用し、マッフル炉、チューブ炉、回転炉、真空・雰囲気炉、CVD/PECVDシステムなどの高温炉を多様な研究所に提供しています。当社の強力な深いカスタマイズ機能により、お客様固有の実験ニーズに合わせた正確なソリューションを保証します。効率を高め、コストを削減し、優れた結果を達成するために、今すぐお問い合わせください。当社の専門知識がお客様の研究室にどのように役立つかご相談しましょう!

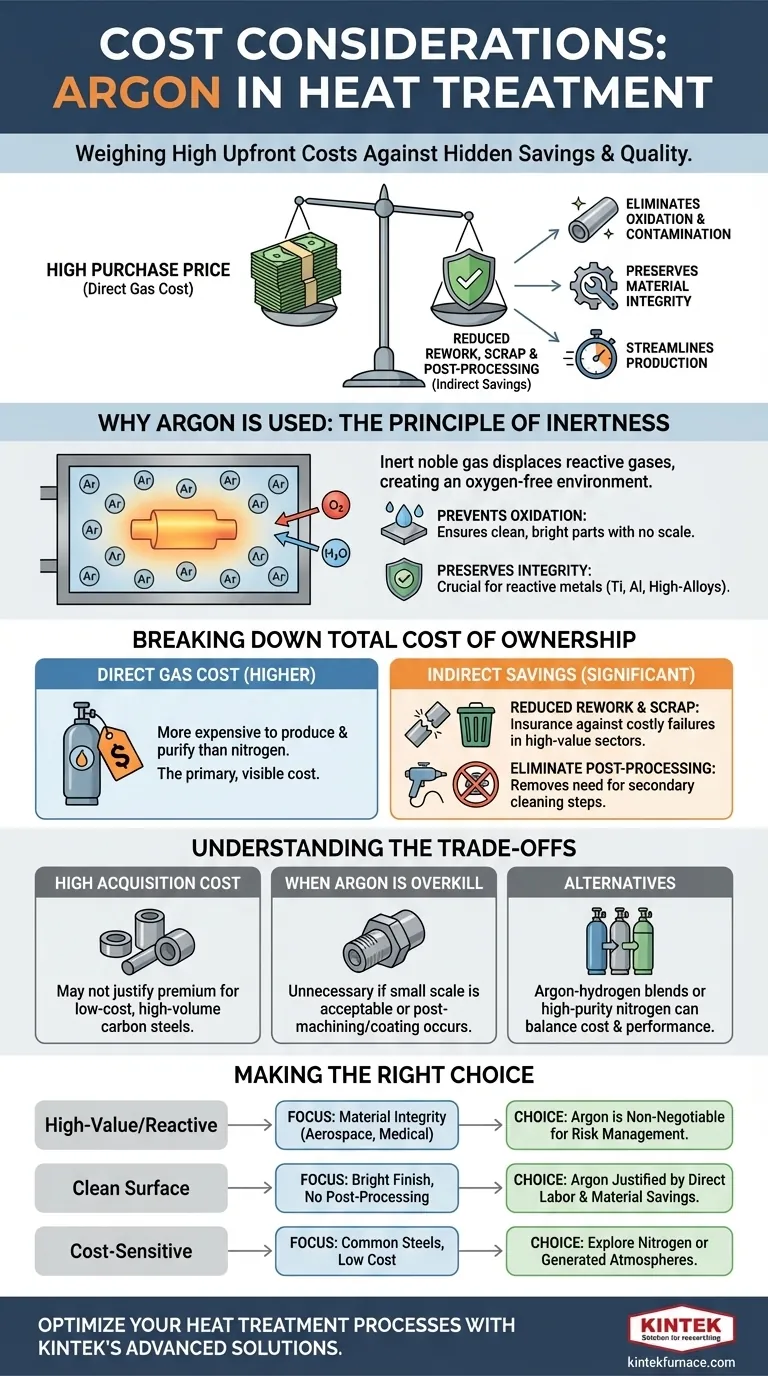

ビジュアルガイド